Turn-On Time is the time to take proper decision for all activities

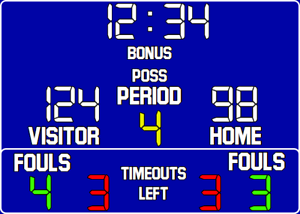

Turn on schedule or rise time is the time needed by a sign to change from low state to high state. The time it takes for the yield of a framework to transform from a predefined little rate (typically 5 or 10) of its consistent state addition to a predetermined enormous rate. A LED’s turn-on-time is the time required by the gadget to abandon the OFF state to ON state. Time is expected to emanate the light, after applying the power. LED Scoreboards allsports are extremely quick gadgets and their turn-on time is 0.0001S or 0.1mS. Polymer light producing diodes (PLED) utilizes an electro iridescent conductive polymer that discharges light when associated with a force gracefully. PLEDs need a modest quantity of power to discharge light and consequently, they are viewed as proficient. A polymer light radiating diode utilizes ionic fluids as one of its dynamic material. Normally polymer light radiating diode has a quick turn on schedule.

Improved Efficiencies in LED helps for the invention of new things

Driven proficiency can be improved by focusing on bundling, chip structure, and positive voltage applying. White LEDs are normally viewed as more productive than the other Red, Green, Blue shading LEDs. White light in LED can be created in two different ways. One technique is, utilizing three individual LEDs which creating the essential tones and afterwards blending them to deliver the white light. Another strategy is, utilizing the rule which is utilizing in glaring lights, phosphor material is utilized to change light from UV or blue LED over to white light. The iridescent effectiveness of blue/UV chip and the changing productivity of phosphorous decide the proficiency of white LED. Radiant proficiency is exceptionally affected by temperature and current. The proficiency of LEDs falls with the expanding current. This impact is called hang. While working temperature increments from 327K to 380K, the glowing effectiveness dropped by 20%. At the point when the temperature is rising, the radiation at the potential abatements which in the long run cause a diminishing in glowing effectiveness. While working current ascents from 0mA to 350mA, the glowing effectiveness of LED will in general be diminished by 35%. At the point when the current expands, an ever-increasing number of non-stable electrons diffuse out of the possible well, accordingly diminishing the glowing effectiveness.

Improvements have to do with all the process of the invention

They can improve the brilliant effectiveness of a LED by improving the warmth dissemination proficiency and expanding the width of the expected well. The working state of a LED should be under restricted temperature and moderate current. The warmth produced in the LED lessens the productivity of lighting execution. A decent pressing innovation is the best approach to take care of the warmth dissemination issue. Be that as it may, building up a warmth dispersal innovation for diminishing the LED’s working temperature is a genuine test. The productivity and unwavering quality of a LED rely upon the warm scattering of a LED, because of the warmth created in the intersection influence the exhibition and compelling activity of LED. Driven productivity can be improved by LED bundling. In any case, they have to overcome the moves looking in the bundling stage to arrive at the ideal effectiveness. The difficulties looking in bundling are shading consistency of light discharging, multi-chip bundling and so forth Bundling innovation utilized for high force LED are more perplexing and exorbitant. Notwithstanding bundling, chip structure and positive voltage likewise assume a function in LED productivity. Proficiency can be accomplished if positive voltage can be controlled in a tiny reach.